Introduction

A protocolo operacional padrão (POP), or Standard Operating Procedure (SOP) in English, is a formalized set of written instructions that outline how to consistently perform a specific task or process. Organizations across healthcare, manufacturing, technology, government, and education rely on POPs to maintain quality, safety, efficiency, and compliance.

In an increasingly competitive world, where mistakes can lead to financial losses, safety hazards, or reputational damage, having clear and standardized procedures is essential. This article provides a deep dive into what a protocolo operacional padrão is, why it matters, how to create one, and how it can transform organizational efficiency.

What is a Protocolo Operacional Padrão?

A protocolo operacional padrão is essentially a blueprint for routine work. It ensures that every team member performs tasks the same way, minimizing variation and reducing errors.

Think of a POP as a roadmap:

- It describes what needs to be done.

- It specifies how it should be done.

- It identifies who is responsible.

- It defines when and under what conditions the task should be carried out.

For example, in a pharmaceutical company, a POP might detail the exact process for labeling medicines to comply with strict government regulations. In IT, it might describe how to perform system backups securely and consistently.

Also Read: PO Box 5622 Manchester – Everything You Need to Know

Importance of Protocolo Operacional Padrão in Organizations

The role of a POP extends beyond efficiency. Its significance can be broken down into several core areas:

- Quality Control

- Ensures uniformity in products and services.

- Reduces errors caused by individual interpretation.

- Compliance and Regulation

- Many industries (healthcare, pharmaceuticals, food production) require SOPs to meet national or international standards.

- A well-written POP can serve as evidence of compliance during audits.

- Training and Onboarding

- Helps new employees quickly adapt to their roles.

- Provides step-by-step references for learning critical tasks.

- Safety and Risk Reduction

- Standardized procedures minimize accidents, especially in hazardous environments.

- Creates accountability by assigning clear roles and responsibilities.

- Operational Efficiency

- Reduces time spent figuring out processes.

- Streamlines communication across departments.

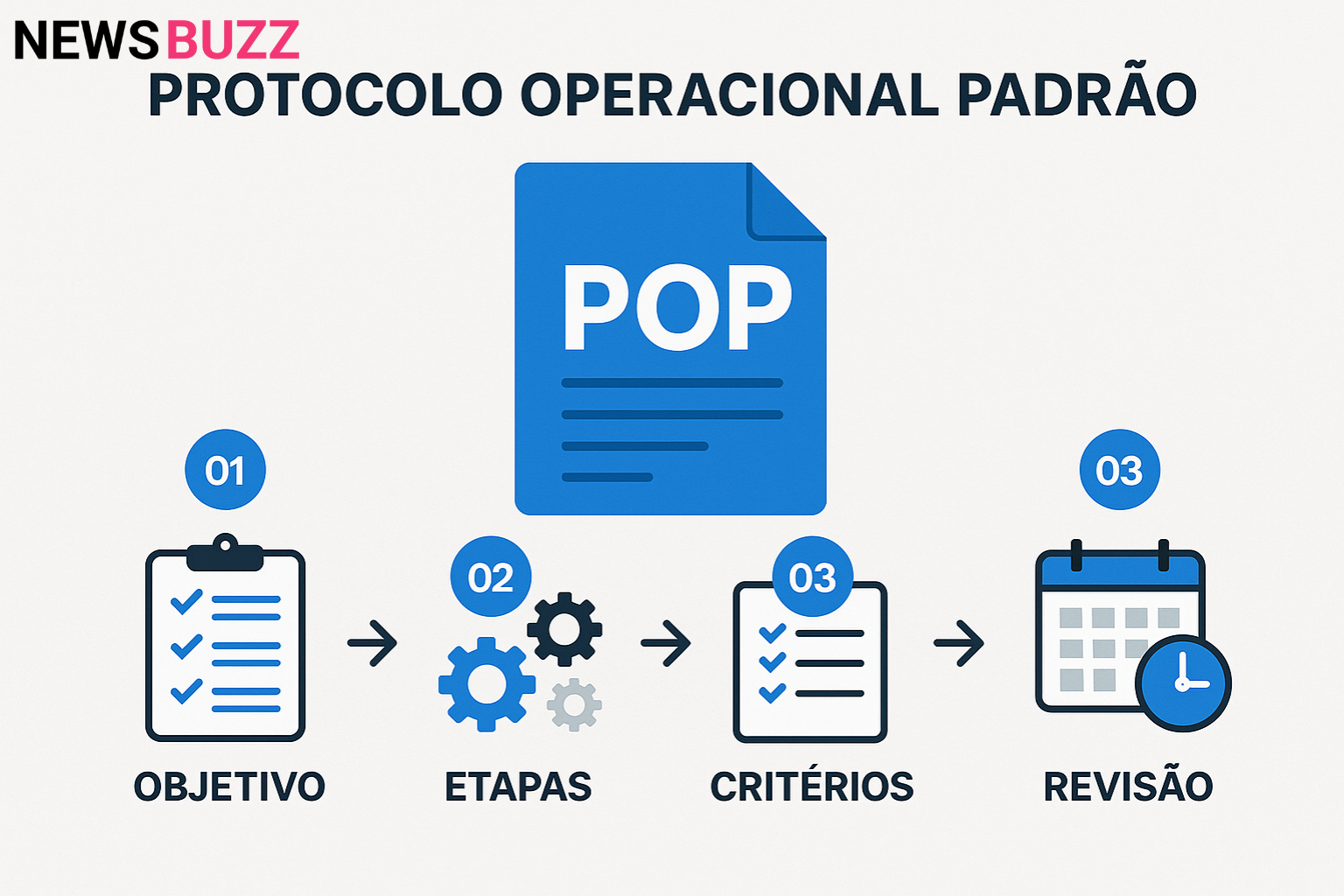

Key Elements of a Protocolo Operacional Padrão

While POPs may vary in format, they usually include the following elements:

- Title and Code: A clear, unique identifier for the process.

- Objective: The purpose of the POP and expected outcome.

- Scope: Defines the areas, people, or situations where the procedure applies.

- Responsibilities: Lists the roles of those who carry out and supervise the process.

- Materials and Tools: Required resources for task execution.

- Procedure: A detailed, step-by-step description of how to complete the task.

- Quality Control Measures: Criteria to verify that the procedure has been done correctly.

- References: Relevant standards, laws, or manuals.

- Revision History: Dates and details of changes made to the POP.

Step-by-Step Guide: How to Develop a Protocolo Operacional Padrão

Step 1: Identify the Process

Determine which task or process requires standardization. Focus on critical activities that impact quality, safety, or compliance.

Step 2: Gather Input

Consult experts and employees who regularly perform the task. Their insight will make the POP practical and realistic.

Step 3: Draft the Procedure

Write clear, simple, and sequential instructions. Avoid technical jargon unless necessary, and ensure that each step is unambiguous.

Step 4: Include Visuals

Where possible, add diagrams, flowcharts, or checklists. These improve comprehension and reduce errors.

Step 5: Review and Validate

Have supervisors and frontline workers test the draft POP to confirm its accuracy and usability.

Step 6: Implement and Train

Roll out the POP across the team, providing training to ensure everyone understands and can follow it.

Step 7: Monitor and Update

Processes evolve, so a POP should be reviewed regularly (at least once a year) and updated whenever systems, regulations, or tools change.

Real-World Examples of POP Applications

Healthcare

- Administering medication dosages.

- Sterilizing surgical instruments.

- Emergency room triage procedures.

Manufacturing

- Quality control in production lines.

- Equipment maintenance schedules.

- Safety checks before machine operation.

Information Technology

- Data backup and recovery procedures.

- Cybersecurity monitoring routines.

- Software update protocols.

Education and Public Administration

- Laboratory safety instructions for students.

- Document approval and archiving processes.

- Emergency evacuation plans.

Advantages and Limitations of POPs

Advantages

- Improves consistency and reliability.

- Reduces risks and increases safety.

- Serves as a training and compliance tool.

- Enhances organizational transparency.

Limitations

- Can become outdated if not regularly revised.

- Overly rigid POPs may reduce flexibility and innovation.

- Poorly written POPs may confuse rather than guide employees.

Also Read: PO Box 795 Telford: Full Guide to Understanding DWP Debt Letters

Conclusion

The protocolo operacional padrão (POP), or Standard Operating Procedure, is more than just a document—it’s a foundation for organizational excellence. By providing clarity, consistency, and control, POPs help businesses and institutions operate smoothly, safely, and in compliance with regulations.

In today’s fast-paced world, where efficiency and safety are non-negotiable, a well-crafted POP is not just a good practice—it’s a necessity.

FAQs About Protocolo Operacional Padrão

1. What industries use POPs most frequently?

Healthcare, pharmaceuticals, food processing, IT, and manufacturing rely heavily on POPs.

2. How detailed should a POP be?

It should be detailed enough to prevent confusion but simple enough for employees to follow without difficulty.

3. Who is responsible for writing POPs?

Usually managers, quality control teams, and subject matter experts collaborate to draft and validate POPs.

4. Are POPs legally required?

In regulated industries like healthcare and food production, yes. In other sectors, they are considered best practices.

5. How often should POPs be reviewed?

At least annually, or immediately if there are changes in technology, regulations, or workflows.