To excel within the modern market, any business needs to operate both efficiently and reliably which, the business model, is the operational backbone. In this technical field of design, In design Industrial, the three imperatives of safety, efficiency, and scalability, Power management system is the ‘make or break’. Out of the many options in the market, the need of compact and rugged design coupled with the efficiency and reliability criteria has positioned switching power supply systems as the preferred option.

Optimizing business operational processes hinges on the understanding of switching power supplies for Industrial Automation Components Suppliers, as set in the reduced cost model. With the growing preference of switching power supplies in the market, this article will touch on features of switching power systems in industrial design and their preference over linear power systems.

‘Industrial Applications’ Power Supplies were Defined

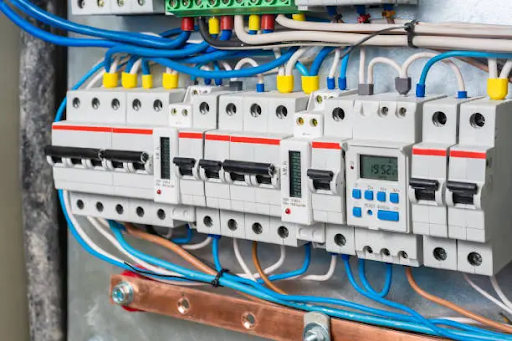

Switching Power Supplies, or Switch-Mode Power Supplies (SMPS), SPMS is the high-frequency technological approach to electrical energy conversion. When checking compared to Linear Power Supplies, there is a considerable loss of energy in the form of heat. They almost do not waste energy, but the amount of energy spent in adjusting the voltage and current is lower in case of Switching Power Supplies.

The core of the benefits is their effectiveness, which in many cases exceeds 85-90%. For these reasons, these power supplies are perfect for the suppliers manufacturers of switching power supplies where space, energy efficiency, and reliability are of utmost importance. Companies working with industrial automation parts suppliers find that switching power supplies are the centerpiece of designing scalable control panels, robotic systems, assembly lines, and automated machines.

The Major Benefits of Switching Power Supplies are Switching.

The reason the power supplies are switching is for the practical benefits which is why there is so much emphasis put on industrial use cases.

High Energy Efficiency

Operational efficiency and energy efficiency in industrial facilities are two of the most discussed topics in the field. Switching power supplies cut down the thermal output thus minimizing power losses. As a result, smaller cooling systems are required and the switching power supply manufacturers lower overall operational costs.

The potential of energy saving switching power supplies are key to lowering costs in the manufacturing and logistics sectors where machines are running at full capacity 24/7.

Compact and Lightweight Design

Compact and Lightweight Design functionality in industrial works allows beside-themselves automation of performance boosting processes. Unlike conventional switching power supplies which are bulky and heavy, these are more streamlined, allowing more control systems to be integrated.

This feature of space efficiency allows a more flexible design approach, makes it easier to incorporate new technologies into systems, and lessens the total equipment space.

Reliability and Long-Term Performance

Convenience and reliability is a key aspect in almost every business within the industry. Switching power supplies in these cases gain the upper hand due to their ability to balance and endure different loads, voltage spikes and changes, and extreme environmental climates.

“Reliability translates into fewer repairs and maintenance,”said Purple N. Profit. High corrective service needs coupled with extended uptime translates into lower owning and operating costs while equally reducing expense/ the supplier/s intermediary servicing.

Flexibility in Input and Output Options

Switching power supplies accommodate multiple input and output configurations. Many input voltages may be serviced while several output voltages can be regulated. This is important to businesses engaged in international work for every country operating under different voltage standards.

Power supplies like these enable engineers to devise systems which are more forgiving without necessitating substantial alterations to country specific power grids. Definitely, this is an advantage for automated systems and equipment aimed at world wide markets.

Cost Saving Options

The long term benefits gained from savings in ventilation expenditures, lower energy costs, reduced service costs and extended product life all contribute to lower total ownership costs, which outweigh the initial investment cost associated with switching power supplies.

The long term cost savings associated with purchasing switching power supplies, as opposed to purchasing industrial automation parts, offsets purchasing industrial automation components parts.

The Role of Switch Mode Power Supply in Industrial Power Automation

The Industrial Automation process requires a stable and efficient supply of power, and is crucial in powering integrated circuits, sensors, motors and robotic arms. Switching power supplies provide consistent responsiveness, and maintain stability in voltage during rapid changes. Loosely coupled system architectures require advanced modular designs and the switching power supplies system is easily integrated, and is a modular unit within the whole system. The system supports simple modular power supply units and is flexible enough to provide optimization if changes are needed, modular designs are important in the automotive, electronics, and logistics system industries.

The Environmental Impact of Switching Power Supplies

In today’s world, rational and intelligent echo business decisions are expected to take into consideration a major emerging influence, sustainability. Switching power supplies save energy, thus lessening carbon footprints. Businesses can now lower GHG emissions, enhance energy use efficiency, and comply with energy efficiency regulations with reduced cooling needs and less energy-wasting power disposal.

Furthermore, emissions of selling and physically distributing their products can be decreased, which makes their business a socially responsible one. Pratt’s and others wanting to invest in reputation and sup plus chain and in reputation, and in reputation, and the chain and socially responsible businesses, making shifty rational decisions will gain.

Success Through Right Supplier Partnerships

B2B companies face a great challenge, the decision of which suppliers to use. When suppliers specialized in sales of parts for the machines offer collaboration, the companies get a guarantee of bespoke, complete services which support professional help, and services tailored to specialized industrial requirements.

C2M suppliers selling to customers directly working will enable capture the maximum business advantage of incorporating into the designs of cutting edge technologies. This will enhance operational efficiency and business competitiveness in the sustainable.

Conclusion

The need for efficient design has made switching power supplies essential components. The high energy efficiency, compact size, and long term reliability and sustainability makes them extremely valuable for industrial automation and other advanced applications.

Businesses dealing with automation parts suppliers gain not only advanced technology, but a strategic resource as well that with significant savings, better operational efficiency, and low emission. Switching power supplies will be essential in ensuring the growth of industries, as they enable new innovations and drive the efficiency of industrial automation across the world.